All about Sheroz Earthworks

Table of ContentsThe Ultimate Guide To Sheroz EarthworksThe 7-Minute Rule for Sheroz EarthworksHow Sheroz Earthworks can Save You Time, Stress, and Money.Sheroz Earthworks - TruthsLittle Known Questions About Sheroz Earthworks.

For any type of earthwork specialist, it is important to perform job with high quality, accuracy, and on routine. Utilizing equipment control in work makers allows maximizing the various phases in the earthwork procedure, from preparing to the upkeep stage - trimble repair parts. The device control system aids the device driver in achieving the target aircraft swiftly and conveniently

The equipment control system guides the driver with centimeter accuracy. With Xsite PRO 3D, you'll always understand specifically just how much to reduce or fill. Your neighborhood Xsite technical assistance can direct you and aid with any type of troubles without visiting the website. Remote support saves money and time, as it lessens downtime in jobsites.

Sheroz Earthworks for Dummies

Additional training and directions are always available over remote assistance when needed. The earthmoving market has actually used our field-proven solutions since the very early 1990s. Our system's parts are carefully designed to stand up to the rough conditions of building sites. Contrast of the very same task implemented using device control versus the standard technique discloses that, typically, the typical technique requires 50% even more time to complete the same job as the technology-assisted method. https://au.enrollbusiness.com/BusinessProfile/6851844/Sheroz%20Earthworks.

Get in the Xsite device control system; it's here to provide you with a considerable benefit when functioning with earthmoving machinery. Discover how Xsite Machine Control can enhance your performance and make sure job safety! Xsite Maker Control systems can be installed to any type of excavator from mini excavators to large mining excavators.

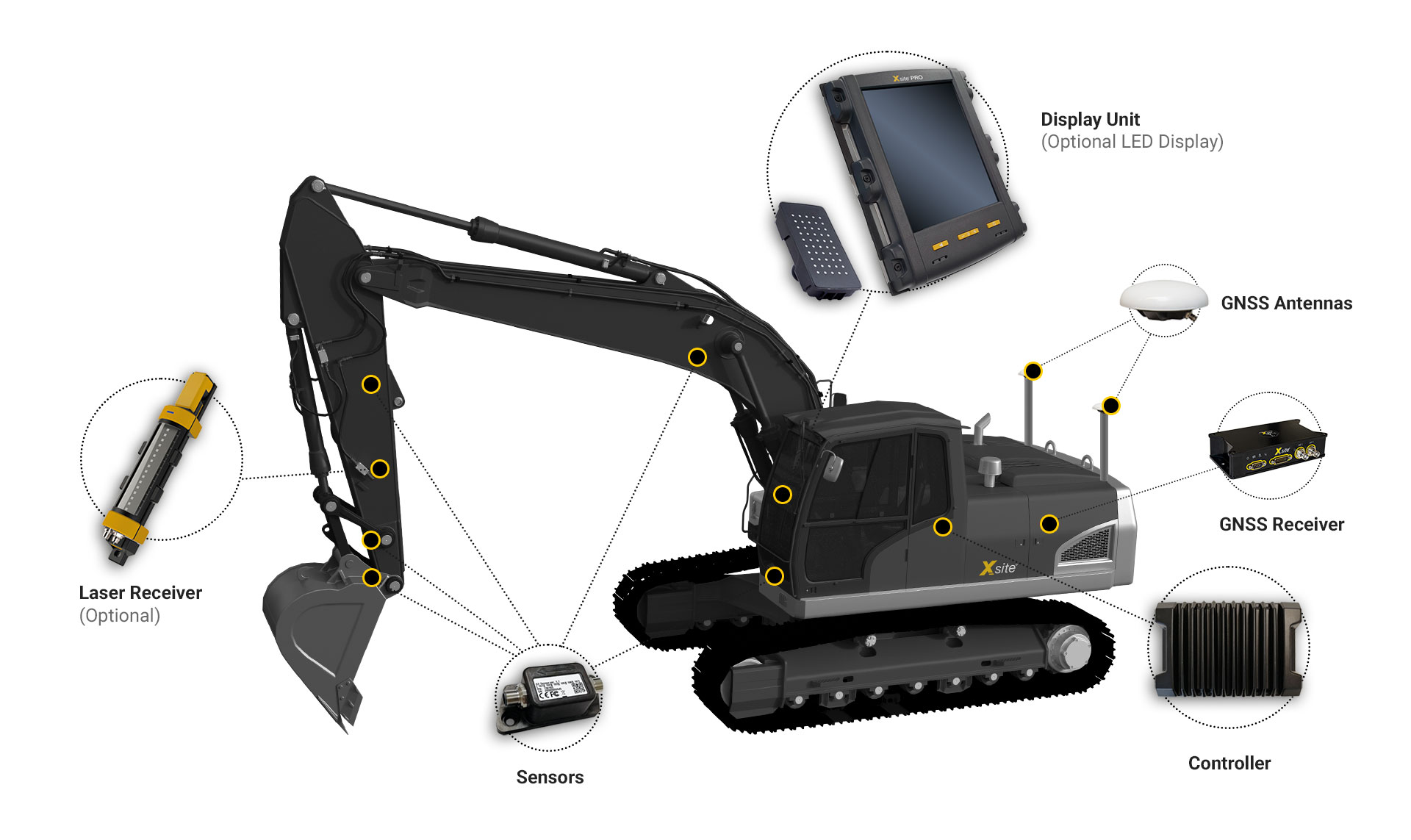

Exactly how does maker control job? In 2D systems, the equipment is furnished with calibrated inclination sensing units. These sensing units are mounted on the pre-determined components of the maker in excavators the sensor are usually installed to the framework, boom (or booms), miner arm and to the fast coupler - trimble parts. By utilizing the information obtained from these sensing units the system can calculate the exact setting of the excavators pail tip in importance to a reference factor.

The system is extremely simple to learn the basics can be taught in under one hour of training. With Xsite you don't need to bother with finding out all the tips and method at when. Extra training and guidelines are always available over remote assistance when required. Contact your regional Xsite dealership to discover even more! Just how does the remote assistance job? A cordless internet link makes it possible to establish a remote connection in between the device control system and the service.

Unknown Facts About Sheroz Earthworks

Xsite Device Control systems sustain open standard file formats, allowing smooth information circulation from one system to another. Depending on your option of system (with or without positioning, i.e., 2D or 3D), your maker is geared up with inclination sensing units, a controller unit, and a display/operating panel.

Several equipment and software options exist to assist figure out an equipment's existing placement on the planet and compare it with a desired style surfaceand construction operators can do more to leverage the benefits. Maker control is the use of numerous placing sensing units and a display screen to offer the driver with a recommendation between the placement of the pail or blade and the target grade.

Depending on the arrangement, machine control systems can provide the driver with a straightforward aesthetic overview to container or blade setting, or can immediately move the blade to quality by speaking with the maker's hydraulics - https://www.artstation.com/floydoverbeck1/profile. There are device control systems available for almost any maker: , dozers, excavators, soil and asphalt compactors, scrapes, trimmers, milling makers, and pavers

The Best Strategy To Use For Sheroz Earthworks

Some benefits consist of minimized rework, enhanced job performance, and reduced evaluating costs. Maker control can likewise assist enhance efficiency and decrease total prices. This modern technology is transforming the method the building market works. Construction tools without equipment control will certainly come to be a point of the past find out here now and the benefits acquired from it will be many.

Trimble device control systems offer a myriad of advantages to anyone that makes use of earthwork machinery and, at EarthCalc, we can offer you with 3D declare your maker control-enable equipment. Not sure if maker control is worth the expense? Take into consideration the complying with factors why you need to consider this alternative.

Making use of GPS lined up with your 3D style files, these systems practically assure that you will eliminate or position the proper amount of material at the building and construction site. On a lot of construction websites, remodel is a typical and frustrating fact, but with Trimble maker control, you can eliminate the demand for rework.

The Definitive Guide to Sheroz Earthworks

Usually, with Trimble equipment control, you can eliminate excess tools at a specific task website. As an example, a work that may have needed the use of three or 4 pieces of digging deep into equipment currently might need only two tools to complete the exact same task in less time. This permits you to relocate your equipment to one more work site and handle several work at one time.